Welding is the most commonly utilized metal fabrication process following which two materials are joined together using heat. Gas flame, a laser, an electric arc, an electron beam, ultrasound or friction are the instruments typically used for welding purposes. Though there are advantages of welding and today the advancement in welding technology is also great, the process still is dangerous and injuries can also occur including electric shock, burns, poisonous fumes, eye damage, and excessive exposure to UV light.

More importantly, not on the welder is in danger but people working nearby are can also possibly be injured from welding works. To prevent harm and to keep the workers secured, welding curtains and strips came into existence.

Since welding procedures involve volatile gases, a solid enclosure can actually turn a ‘not so good’ environment into something worse, as in such situations good ventilation arrangements are vital. Here, welding grade PVC strips can be used to reduce the risk of injury to workers present in the place but not directly involved in the welding process.

Generally, the welders use complete safety gear but the staff members who assist them hardly use anything. These members can also be adversely affected by the weld arcs or the ultra-bright light that comes from the welding cabin/booth that can lead to corneal irritation or ‘arc eye’. Therefore, the PVC strips can prevent such injuries while protecting workers from sparks, smoke, and light.

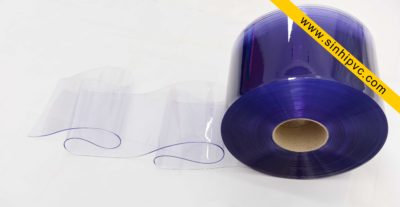

Welding grade PVC strips are made of a strong polyvinyl chloride (PVC) which allows is to be either completely transparent of slightly tinted (colored). The strips can be bought in rolls so that they can meet the requirements of each customer. Buyers can simply cut them as per the application and punch them so that they can be hung. They come in various tints such as green, grey, orange, and plain translucent; however, the most popular colors are dark red and green. Buyers can choose any as per the level of protection.

The characteristics of a good quality PVC strip are:

- High R-Value

- Flame resistance

- Resistant to harsh chemicals

- Resistant to mildew

- High tensile and tear strength

- Protection against heat damage

- Cold crack resistance

Because of the obvious dangers of welding, it is highly important to adopt all the required safety measures for the welders, their assistants, and all other workers working in the same place. Injuries can happen anytime within seconds and some may lead to severe conditions, therefore, the level protection these PVC strips provide is appropriate to reduce minor incidents or accidents.

Welding grade PVC strips are highly customizable to get the desired level of protection and proper fit. They deliver a valuable service in welding related safety precautions that are essential in the industry and suggested by labor protection laws in China and Hong Kong.