Amidst the myriad of safety measures in workplaces, there’s an unsung hero – flexible PVC strips. Often underestimated, these strips play a crucial role in enhancing safety across diverse work environments. Let’s explore how these unassuming strips contribute significantly to ensuring a secure and efficient workplace.

Understanding Flexible PVC Strips

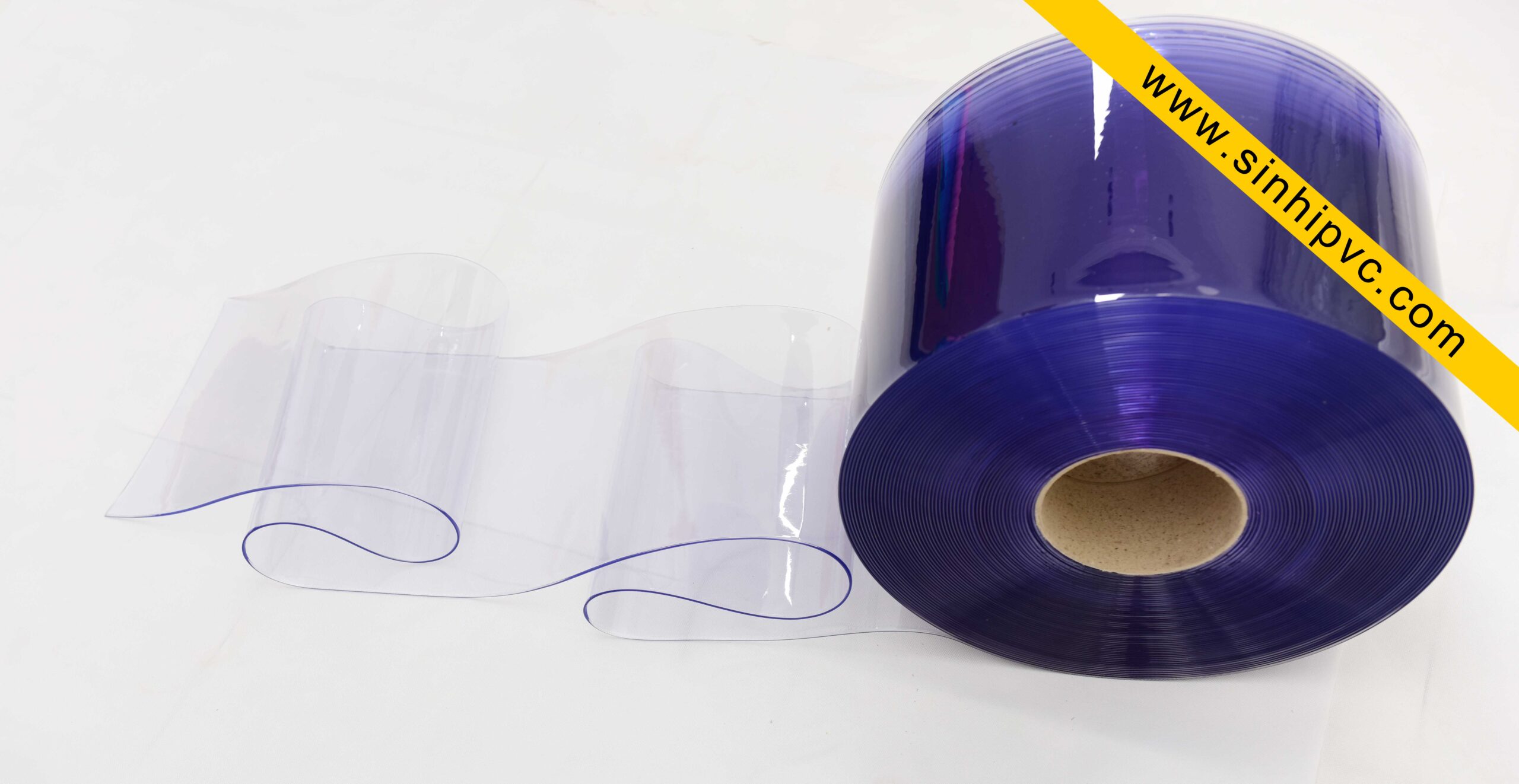

Flexible PVC strips, often seen in industrial settings, serve as versatile partitions or barriers. These strips are made from durable, flexible polyvinyl chloride (PVC) material. Here’s how they enhance workplace safety:

Material Composition: Flexible PVC strips are constructed from high-quality PVC, offering durability and resilience against wear and tear.

Adaptability: They come in various widths, thicknesses, and colors, allowing for customization based on specific workplace requirements.

Ease of Installation: These strips are easy to install and can be hung or mounted to create partitions or barriers as needed in different workplace areas.

Promoting Safety in Work Zones

Controlling Environmental Elements: PVC strips act as barriers, preventing the ingress of unwanted elements such as dust, debris, or pollutants into sensitive areas. They help maintain a clean and controlled environment, especiCally in manufacturing, warehouse, or food processing settings.

Temperature Control: In workplaces where temperature regulation is crucial, such as cold storage units or areas with varying temperatures, PVC strips act as insulators. They help maintain appropriate temperatures by minimizing the transfer of heat or cold air, ensuring employee comfort and energy efficiency.

Noise Reduction: These strips also aid in noise reduction by acting as sound barriers, minimizing noise pollution between different zones within a workplace. This is particularly beneficial in manufacturing facilities with loud machinery.

Enhancing Safety for Employees

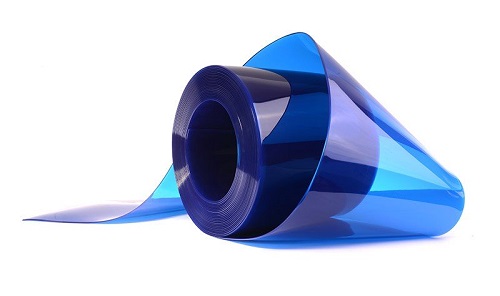

Improved Visibility: PVC strips are available in transparent options, allowing visibility across different sections while providing adequate separation. This transparency enhances safety by allowing employees to see through the strips, reducing the risk of collisions or accidents.

Preventing Accidents: The flexibility of these strips acts as a safety feature. In high-traffic areas, they bend upon contact, reducing the impact of collisions and mitigating the risk of injuries or accidents.

Ergonomic Advantage: PVC strips are easy to pass through, providing a convenient passage for workers, forklifts, or machinery. Their flexibility allows quick and effortless movement without the need for manual opening or closing of doors.

Cost-Effectiveness and Maintenance

Cost Efficiency: PVC strips are a cost-effective solution compared to traditional rigid barriers or doors. They require minimal initial investment and offer long-term benefits in terms of safety improvements and operational efficiency.

Easy Maintenance: Maintenance of PVC strips is simple. Cleaning can be done using mild detergents and water, ensuring a hygienic environment. Additionally, replacing damaged strips is straightforward and cost-effective compared to fixing rigid barriers.

Longevity: Due to their durable material, PVC strips have a long lifespan, providing sustained safety benefits over time without requiring frequent replacements.

Conclusion

Flexible PVC strips play a vital role in enhancing workplace safety. They offer versatility, control environmental elements, promote safety in work zones, enhance employee safety, and are cost-effective while being easy to maintain. Embracing these simple yet effective solutions contributes significantly to a safer and more efficient work environment.