Dust easily builds up in Manufacturing Plants. Exhausting fumes, black marking tires, frequent movement of cardboard boxes and wooden pallets, and dust inflow from outside are among several reasons that lead to dust buildup in a factory.

While small amounts of dust have little to no side-effects on anyone and anything, the presence of higher amounts of dust can be dangerous. Lack of regular maintenance and cleaning can further aggravate the issue.

Do you not agree? Let’s check out how large dust accumulation can be dangerous for your factory or warehouse.

Poses Serious Health Risks on Employees

Exposure to dust particles on regular basis can irritate the skin, eyes, respiratory system, and even ears. Allergies in such working spaces are common. Even if your employees spend just a few hours in such places, they are prone to serious long-term illnesses.

For instance, silicosis is a fatal and incurable lung disease caused by breathing in dust that contains crystalline silica.

In severe cases of dust accumulation on the floor, it can also lead to increased slipping accidents.

Reduces the Efficiency of the Equipment

When regular cleaning and maintenance are not carried out, dust starts to accumulate on equipment, machinery, and plants. When enough dust builds upon them, it causes performance issues. They work with poor efficiency and maintenance costs rise significantly.

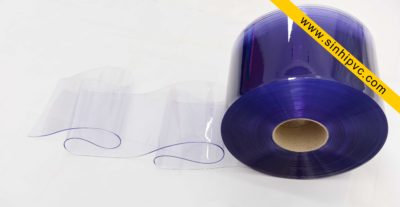

PVC String Curtain Holder

The downtime caused by poor functioning and efficiency will also cause further losses. Besides, it gets difficult to move materials on the floor if there is too much dust on the floor.

Internal parts and components can get clogged or even damaged. Sometimes, it may also lead to shorts in electrical circuits.

In short, when dust builds up at higher levels in your workshop, it will be at constant risk of fire accidents and poor productivity.

Has Direct Risks of Hazardous Accidents

One of the most hazardous things that can happen with greasy dust buildup is the combustive dust explosion. When dust accumulates at higher levels and it comes into contact with an ignition source, it can result in an explosion, which put the safety of your employees and facility at a huge risk.

To the surprise of many, such cases of the explosion are common. Thus, factories and warehouses are required to adopt good housekeeping practices. Failing to do so can make you pay large fines and prone to the risk of hazardous explosions.

So, what to do to avoid the risks and prevent dust accumulation?

- Ensure regular checkup and cleaning, and make it a part of the normal maintenance routine. While most surfaces can be cleaned with water, some surfaces, equipment, and electronics may need special cleaning agents.

- Use microfiber cloths for dusting purposes as they attach themselves with small dust particles. Dusting at least every weekend ensures that equipment will not lead to major failures.

- Analyze the traffic flow in your facility and reduce the traffic as much as possible.

- Install PVC String Curtain Holders at suitable places that act as entry or exit and hang dust control PVC strip curtains. If there is only one entrance and the working space is large, then prefer creating partitions to minimize dust accumulation and ensure noise control.

With these simple tips and cautiousness, you can easily prevent the risks and dangers caused by dust accumulation.