All of us know that welding is counted as one of the most dangerous tasks. Not only welders are at risk, but other people working in the vicinity are potentially exposed to injuries and burns. In workshops, automobile service centers, and other places where welding is performed, it is important to take necessary precautions for the safety of workers and surroundings. One of the most effective ways to create a safe zone in welding areas is to install welding screens and curtains.

Welding Screens and Curtains!! What are they?

Welding screens and curtains are just like PVC strip curtains. They are made from laminate opaque vinyl with 400 pounds of tensile strength and can be easily placed in any area where welding activities and operations are carried out. They can be colored or transparent based on the welding category or concerning issues.

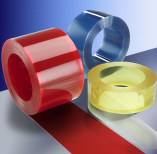

- Yellow Welding Screen – for welding environments that involves low to medium amperage

- Orange and Red Welding Screen – for medium amperage welding facility

- Blue Welding Screen – for medium to high protection and blocking out ultraviolet radiations

- Dark Green Welding Screen – for plasma cutting and laser welding facilities

In some places, these welding screens are fitted with rings for easy sliding.

Do I need to install welding screens?

Though you can use welding screens in any place where welding operations take place, it is highly beneficial and even recommended to install them in those facilities that don’t have an enclosed area or separate welding area.

Once you install them properly, it can help you minimize the workers’ injuries caused by sparks as well as nerve and lung damage due to toxic chemicals, flash burns, and arc eye.

How do welding screens enhance welding protection? What are they made of?

Welding screens are generally made from strong polyvinyl chloride and treated by fire-retardant chemicals. As such, it’s hard for them to catch fire when they come into contact with stray sparks. Besides, they also contain a compound that helps in absorbing ultraviolet rays and color dye is utilized in their fabrication process.

Welding screens are highly beneficial owing to their remarkable features and qualities, such as:

- Flame resistance – A property that resists the burning process when the material comes into contact with an ignition source.

- High R value – A parameter that indicates resistance against the conductive flow of heat.

- Chemical resistance – It means the welding screen will remain unaffected or least affected by harsh chemicals.

- Mildew resistance – A property that helps in discouraging the growth of mildew.

- Resistant to heat damage – A quality that shows that the screen will resist excessive heat and the potential damages caused by it.

- High tear resistance – A feature that depicts that the screen won’t tear down easily and thereby, can be used for a long time.

- High tensile strength – This feature refers to that screen can endure a higher amount of stress.

- Cold crack resistance – It means that the screen will not be damaged or degrade when exposed to very low temperatures.

So, if you also have a facility without a separate welding area to carry out welding operations, buy welding screens right away and protect your workers from many possible injuries.